Makersplayce

Neem contact met ons op

Heb je een vraag of ben je benieuwd waar Makersplayce jou bij kan helpen? Laat het ons weten.

Stuur ons een mail

Makersplayce

Makersplayce is de werkplaats binnen Nexus waar Engineering studenten elkaar ontmoeten, projecten tot leven brengen en ideeën uitwisselen. Of het nu gaat om een privé opdracht of studieproject, Makersplayce is de engineering hub waar creatieve ideeën ontstaan.

Onze missie is eenvoudig: Fontys Engineering studenten voorzien van de ruimte, gereedschappen en middelen die ze nodig hebben om te werken aan hun persoonlijke projecten en leerdoelen. Van 3D-printers in een volledig uitgeruste werkplaats tot cursussen en workshops om je kennis en vaardigheden te verbeteren. Makersplayce biedt een breed scala aan mogelijkheden.

Iedereen is altijd welkom om langs te komen!

Bij Makersplayce kan ik mijn creativiteit kwijt!Ties

Cursussen

Ongeacht je niveau of interessegebied, onze cursussen en workshops zijn ontworpen om je te helpen slagen. Of je nu geïnteresseerd bent in 3D-printen of de wereld van programmeren met Arduino wilt verkennen, we hebben voor ieder wat wils. Hou de Makersplayce agenda pagina in de gaten en meld je aan voor een cursus.

Agenda

- 3D Printing Masterclass | 23 oktober 2025

- PCB Design Course | 20 november 2025

- Welding Course | 4 december 2025

- Soldering Course | 18 december 2025

Faciliteiten

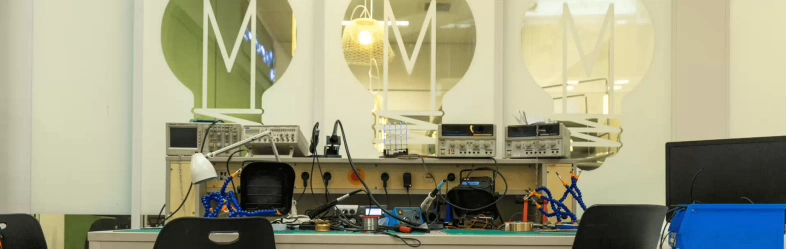

Elektronica werkruimte

Of je nu LED-strips soldeert of je eigen printplaten maakt, de elektronicahoek heeft alle machines die je nodig hebt. We hebben: een compleet soldeerstation | een functiegenerator | een oscilloscoop | logic analyzers | en multimeters.

FDM printers

FDM-printen is een 3D print techniek waarbij gebruik gemaakt wordt van gesmolten plastic. De spuitmond beweegt over drie assen waardoor elke creatie gemaakt kan worden. Ook wel Additive Manufacturing genoemd.

Resin Printer

Resin printen (ook wel vat polymerisatie genoemd) werkt met kunsthars die uithardt bij contact met UV-licht. Door de LCD als 'masker' te gebruiken voor een UV-lamp, kan elke laag in een keer uitharden. Dit proces is geschikt voor zeer gedetailleerde objecten.

Cricut Maker 3

De Cricut Maker 3 is een krachtige knutselmachine waarmee je kunt tekenen, reliëf maken, graveren, perforeren en snijden in verschillende materialen zoals papier, vinyl, dunne houtsoorten en stoffen.

Naaimachines

Naaien is een handige vaardigheid voor zowel productontwikkeling als voor het onderhoud van je eigen spullen.

Computer stations

Krijg toegang tot computers die uitgerust zijn met software zoals SolidWorks en Fusion 360. Dit zorgt ervoor dat projecten met precisie en efficiëntie ontworpen en gemodelleerd kunnen worden. Of maak gebruik van de drie monitoren om je ontwerp- en modelleerwerk te verbeteren.

Gereedschapskisten

Met een ruim assortiment aan gereedschap kan elke klus geklaard worden. Er zijn vier algemene gereedschapskisten, twee gespecialiseerde gereedschapskisten en een gereedschapskar in de bewerkingsruimte.

Vacuümvormer

De vacuümvormer is een Formech Compac Mini. De machine maakt gebruik van de smelteigenschappen van thermoplasten (smeltbare kunststoffen) zoals ABS, PET, PMMA, HIPS en nog veel meer.

Tools

Voor het geval je meer kracht of snelheid nodig hebt bij je project, bieden we ook een assortiment elektrisch gereedschap en speciale apparatuur. Een greep uit het assortiment: een slagmoeraanzetter, twee accuboormachines, een oscillerende multitool en een dremel.

3D-printen

Bij Makersplayce vind je bijna 30 3D-printers waaronder: Ultimakers, BambuLabs en zelfs een Nexakunsthars-printer. Voor studieprojecten kun je gratis gebruikmaken van de printers. Voor privéprojecten worden de materiaalkosten in rekening gebracht. Er is voldoende materiaalkeuze. Zo is er PLA voor algemene prototypes. PET-G voor objecten die chemisch resistent moeten zijn of voedselveilig. Daarnaast is er zelfs filament met koolstofvezel om zeer sterke onderdelen te kunnen printen en TPU als iets flexibel geprint moet worden.

Als je zelf iets uitgeprint wilt hebben, kan dit heel makkelijk via de portal waar je een formulier met al jouw voorkeuren kunt invullen. Nadat je dit formulier hebt ingevuld, zul je automatisch op de hoogte gehouden worden via de mail of kun je de status van jouw print volgen via Trello.

Vul je 3D-print order in via de portal Volg de status van je print via Trello

Foto gemaakt door: Krisjanis Ulmanis

Contact

Of je nu al precies weet welke ondersteuning je zoekt of gewoon wilt verkennen wat Makersplayce voor jou kan betekenen, wij staan voor je klaar!

Makersplayce

Je vindt ons in het Atrium van gebouw Nexus in Eindhoven.